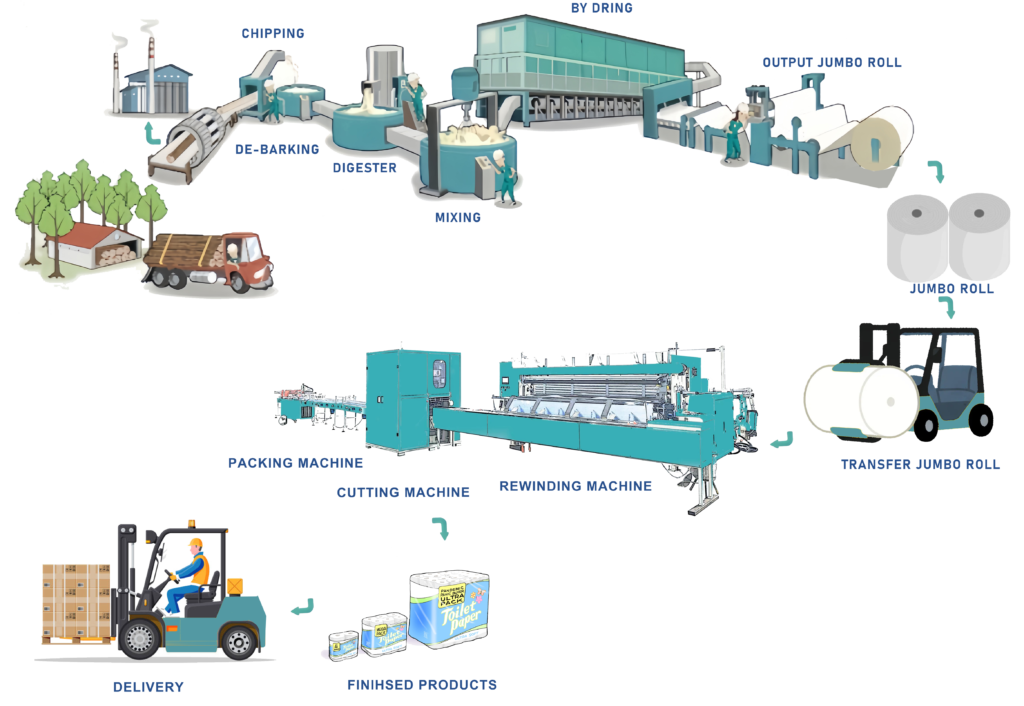

Toilet paper is made by many steps process, involves the transformation of raw materials, typically wood pulp, into the soft, absorbent paper we use every day. Let’s talk about these steps.

1. Raw Material Preparation:

- Pulping:Wood pulp is the primary material of toilet paper, which is derived from either softwood trees (like pine and spruce) or hardwood trees (like oak and eucalyptus). The wood will be debarked and then chipped into small pieces.

- Pulp Production:The wood chips are mixed with water and chemicals to break down the wood fibers into pulp. This can be done using either mechanical pulping (grinding the wood) or chemical pulping (using chemicals to dissolve lignin, the substance that binds wood fibers together).

2. Pulp Refining:

- The pulp is further refined to improve the quality of the fibers. This process helps to enhance the softness, strength, and absorbency of the final product.

3. Bleaching:

- To help the paper into white color, the pulp is bleached using chlorine dioxide or other environmentally-friendly bleaching agents. This step removes any residual lignin and other impurities, brightening the pulp.

4. Paper making:

- Water Removal:The bleached pulp is diluted with water to form a slurry that is 99% water and 1% fiber. This slurry is spread onto a large mesh screen in the paper machine, allowing water to drain away, leaving a mat of fibers.

- Pressing and Drying:The wet mat of fibers is pressed through a series of rollers to remove even more water and then dried using heated rollers. This forms a continuous sheet of paper.

- Creping:The dried paper is scraped off the roller using a blade, which gives it a slightly wrinkled texture. This process, known as creping, increases the paper’s softness and flexibility.

5. Converting:

- Reeling:The large rolls of creped paper are wound into giant reels.

- Cutting and Rewinding:These large reels are then cut down into smaller, manageable rolls. The paper is rewound into the familiar toilet paper rolls.

- Embossing (Optional): Some paper roll will undergoes embossing and printing to improve softness and absorbency.

6. Packaging:

- The paper roll will cutting to different size and packed with different packing style, which is plastic wrapping or other materials, and then shipped to retailers for sale.