Strat a napkin manufacturing business needs several steps, including understanding the market to setting up production and distribution. This is a detailed guide to help you start a new napkin business.

1. Market Research and Business Planning:

Market Research:

Analyze the demand for napkin paper in your target market. Understand the competition, consumer preferences, and price points. Identify any gaps in the market, such as eco-friendly options or custom-printed napkins.Business Plan:

Develop a detailed business plan outlining your business model, target market, production process, pricing strategy, marketing plan, and financial projections. This plan will guide your operations and help attract investors or secure loans.

2. Choosing Your Business Model:

Manufacturing:

Focus on producing napkin paper from raw materials, which requires investment in machinery and raw materials.Private Labeling:

You could also consider producing napkins for other brands or retailers under their labels.Customization:

Offering customized napkins for events, restaurants, or businesses can be a niche market, allowing for higher margins.

3. Legal and Regulatory Requirements:

Business Registration:

Register your business with local authorities and obtain the necessary licenses and permits.Environmental Compliance:

Ensure your production process adheres to environmental regulations regarding waste management and emissions.Health and Safety:

Implement workplace safety measures and ensure compliance with local labor laws.

4. Setting Up Manufacturing:

Production Facility:

Secure a location for your manufacturing plant. Consider factors like proximity to raw materials, labor availability, and transportation logistics.

- Raw Materials:Secure a steady supply of raw materials, which may include wood pulp, recycled paper, and chemicals for processing. If producing eco-friendly napkins, consider sourcing sustainable materials like bamboo pulp.

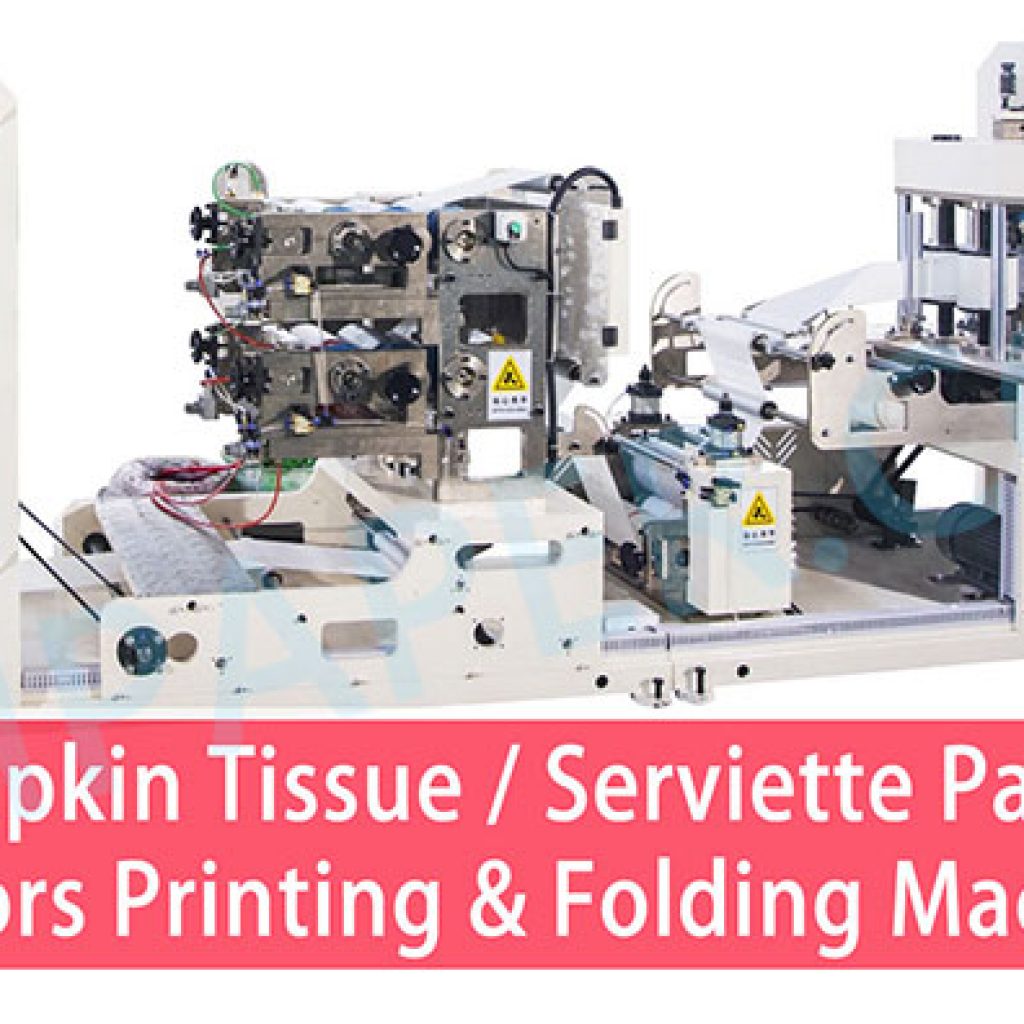

Machinery and Equipment:

Purchase the necessary machinery for napkin production. Key equipment includes:

Pulping Machine:

If starting from raw pulp, this machine processes wood pulp or recycled paper into a usable pulp.

Napkin Paper Machine:

This machine converts pulp into napkin paper, including processes like embossing, folding, and cutting.

Cutting Machine:

Used to cut the napkins to the desired size.

Packaging Machine:

Automatically packs the napkins into plastic wrapping or boxes.

5. Product Development:

Quality Control:

Establish quality control processes to ensure your napkins are soft, absorbent, and strong. Consistent quality is key to building a reliable brand.Variety:

Offer a range of products to meet different market needs, such as cocktail napkins, dinner napkins, or branded/customized napkins.Packaging:

Develop attractive and functional packaging that reflects your brand. Packaging should be durable to protect the napkins during transport and appealing to consumers.

6. Supply Chain and Distribution:

Logistics:

Develop an efficient distribution network to deliver your products to retailers, wholesalers, or directly to consumers. This may involve partnerships with logistics companies or setting up your own distribution system.Retail Partnerships:

Build relationships with supermarkets, retailers, and restaurants to stock and sell your napkins. You may also consider selling directly to consumers through online platforms.Inventory Management:

Implement a robust inventory management system to avoid overproduction or stock shortages.

7. Marketing and Sales:

Branding:

Create a strong brand identity that resonates with your target audience. This includes a memorable logo, packaging design, and consistent messaging.Marketing Strategy:

Use a mix of traditional and digital marketing to promote your products. This could include social media marketing, partnerships with events or restaurants, and online advertising.Customer Feedback:

Encourage customer reviews and feedback to improve your product and build brand loyalty.

8. Financial Management:

Initial Investment:

Secure funding for your initial capital investment, which includes machinery, raw materials, labor, and marketing. This may come from personal savings, loans, or investors.Cost Control:

Monitor production costs closely to ensure profitability. Negotiate with suppliers to get the best prices for raw materials.Pricing Strategy:

Set competitive prices that cover your costs while offering value to customers. Consider offering bulk discounts to attract large buyers like restaurants or event planners.

9. Sustainability and Innovation:

Eco-Friendly Options:

Consider producing eco-friendly napkins using recycled materials or sustainable resources. This can help you tap into the growing market for green products.Product Innovation:

Stay ahead of industry trends by investing in R&D to develop new products or improve existing ones. For example, you could develop napkins with enhanced absorbency or unique designs.

10. Scaling and Growth:

Expansion:

Once established, consider expanding your product line to include related products like paper towels, tissues, or toilet paper.Export Opportunities:

Explore international markets to grow your business, especially in regions with high demand for hygiene products.Franchising or Licensing:

If your business model proves successful, you might consider franchising or licensing your brand and production methods to other regions.