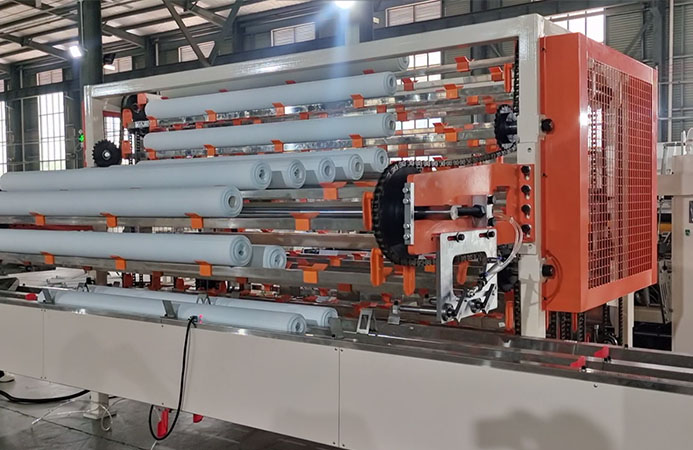

The working process of toilet paper rewinder is:

- Jumbo roll automatic lifter on back standing

- Web feeding

- Perforating

- Fullembossing

- Semi-finished roll pushing out

- New paper core feeding

- Tail cutting and sealing

- Lay-on roller pressing new core

- Semi-finished roll ejecting

Many customers also require embossing toilet paper.

One set embossing roller include one steel roller and one rubber rolls, we also will be provide different design for you, please check the following:

Embosseing Pattern

Embosseing Pattern

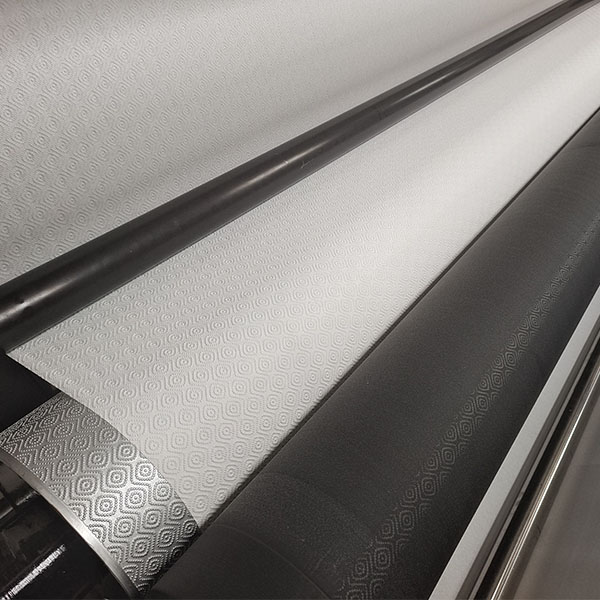

Embossing Roller

Embosseing Product

The semi-finished toilet paper roll first passes through the semi-finished roll log accumulator, and then is cut by the band saw paper roll cutting machine, finished toilet paper rolls are produced after cutting.

This is log accumulator, we have 63 model, 100 model, and 200 model, that can let the product line running stable.

We designed a economic cutting machine for the customer, the finished cutting diameter is 80-130mm, So that can meet most of the size of the toilet roll. The speed also can match 130 rolls/min, that is suitable for connect the product line.

In terms of functions, Our band saw cutter has unique functions such as:

Automatic half-finished roll feeding + storage trough

Fully automatic electric/air knife sharpener + vacuum cleaning

Quick specifications change and sand wheel angle adjustment

Quick pneumatic and hydraulic blades exchange

All the above functions can finally lead to a better band saw cutting effect and high cutting efficiency.

Finished toilet paper rolls are transported by conveyor belts to the packaging machine.

Speaking of toilet paper roll packaging machines, some large-width, large-diameter finished toilet paper rolls are individually packaged and sold.

The finished cutting effect please check the following picture:

Then the toilet roll will be automatic put into the multi rolls packing machine, We designed a fully automatic packing machine can pack 4-48 rolls in a bag.

Through the above text, you have a general understanding of the toilet paper roll’s manufacturing process, many other details about the toilet paper making machine are still waiting for you to discover.

You are welcome to send us an inquiry on this website, we will explain to you in more detail, understand your real needs, and develop the most suitable solution for you.

With the high performance of tissue paper-making machines and its ability to utilize waste paper, JORI is regarded as the fastest-developing manufacturer with a global reach.

JORI designs machines that are worldwide desired due to the advanced technology and multi-functioning.

It is establishing a successful future for your wide range of clients maximizing the industrial competence and technological adeptness of its leaders and team members.

Toilet tissue paper roll making machine is wide in business, as the world demands the toilet paper in bulk.