Material of toilet tissue paper have two types of pulp: Virgin Pulp and Reycled Pulp. The Specific material used in making toilet paper include:

1. Virgin Pulp:

Wood Pulp:

This is the most common material used in toilet paper production. Wood pulp is derived from both softwood trees (like pine and spruce) and hardwood trees (like oak and eucalyptus). Softwood pulp provides longer fibers, which give the paper strength, while hardwood pulp offers shorter fibers, contributing to softness.Bleaching Agents:

Virgin pulp is often bleached to achieve the desired whiteness and to remove any residual lignin (a natural component of wood). Chlorine dioxide, oxygen, ozone, and hydrogen peroxide are common bleaching agents, with chlorine dioxide being used in more environmentally friendly processes known as Elemental Chlorine-Free (ECF) bleaching.

2. Recycled Pulp:

Recycled Paper:

Toilet paper can also be made from recycled paper, which includes post-consumer content (like old newspapers and office paper) and pre-consumer content (like scrap paper from manufacturing). The paper is collected, cleaned, and processed to remove inks, adhesives, and other contaminants.Deinking Chemicals:

In the recycling process, chemicals are used to remove ink and other residues from the paper. This can include soaps, surfactants, and other agents that help to separate the ink from the fibers.Bleaching (Optional):

Recycled pulp may be bleached to improve its color and purity, though this step is less common for eco-friendly products aiming to minimize chemical use.

3. Additives:

Water:

Water is used extensively throughout the pulping and papermaking process to help break down the fibers and form the paper sheets.Binders and Fillers:

Sometimes, small amounts of additives like binders (to improve paper strength) or fillers (to increase opacity and smoothness) are used. These can include starches, clays, or calcium carbonate.Softening Agents:

To enhance the softness of the toilet paper, manufacturers may add softening agents during the production process.

4. Specialty Materials:

Bamboo or Other Plant Fibers:

Some eco-friendly or premium toilet papers use alternative fibers like bamboo, which is highly sustainable due to its rapid growth rate. Bamboo pulp is strong and soft, making it an increasingly popular choice.Fragrance or Lotion:

In some premium toilet papers, fragrances or lotions may be added to provide a pleasant scent or to offer extra skin comfort.

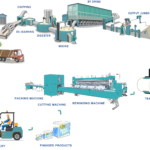

Paper Making Process:

Once the pulp is prepared, whether from virgin or recycled sources, it is processed in large paper machines to form thin sheets. These sheets are then creped (scraped off the machine to create a slight texture), dried, and rolled into large rolls. The rolls are then cut into individual toilet paper rolls, packaged, and distributed.

In summary, toilet paper is made from wood pulp (virgin or recycled), and may include various chemicals for bleaching, softening, and binding. Eco-friendly alternatives often incorporate recycled materials or sustainable fibers like bamboo.