Paper towels are made by a series of processes , which convert raw materials, primarily wood pulp, into the absorbent sheets used in kitchens, bathrooms, and other seeting. Now let’s talk about the key steps about the manufacturing of paper towels.

1. Raw Material Preparation:

- Wood Pulp: The primary raw material for paper towels is wood pulp, which is derived from both softwood trees (such as pine and spruce) and hardwood trees (such as oak and eucalyptus). The wood is first debarked and then chipped into small pieces.

- Pulping Process: The wood chips are mixed with water and chemicals in a digester to break down the wood fibers into a slurry of pulp. This can be done through either mechanical pulping (using grinding to physically break down the fibers) or chemical pulping (using chemicals to dissolve lignin, the substance that binds the fibers together).

2. Pulp Refining:

- The pulp is refined to improve the quality of the fibers, enhancing the strength and absorbency of the paper. The refining process helps make the fibers more flexible and better suited for forming paper.

3. Bleaching:

- To produce white paper towels, the pulp is often bleached using chlorine dioxide, oxygen, ozone, or hydrogen peroxide. This process removes any remaining lignin and brightens the pulp. For eco-friendly products, manufacturers may use elemental chlorine-free (ECF) or totally chlorine-free (TCF) bleaching methods.

4. Papermaking Process:

- Forming the Sheet:The refined and bleached pulp is diluted with water to create a slurry, which is then spread onto a large mesh screen on the paper machine. As the water drains away, a mat of fibers forms on the screen, creating a continuous sheet of paper.

- Pressing:The wet sheet is passed through a series of rollers to remove more water and compress the fibers, which increases the paper’s strength.

- Drying:The sheet is then dried using heated rollers or air drying. The drying process removes most of the remaining water, leaving a dry sheet of paper.

- Creping:The dried paper is scraped from the drying cylinder with a blade, creating a slight texture known as “creping.” This process gives the paper its characteristic softness, flexibility, and absorbency. Creping also increases the surface area of the paper, making it more absorbent.

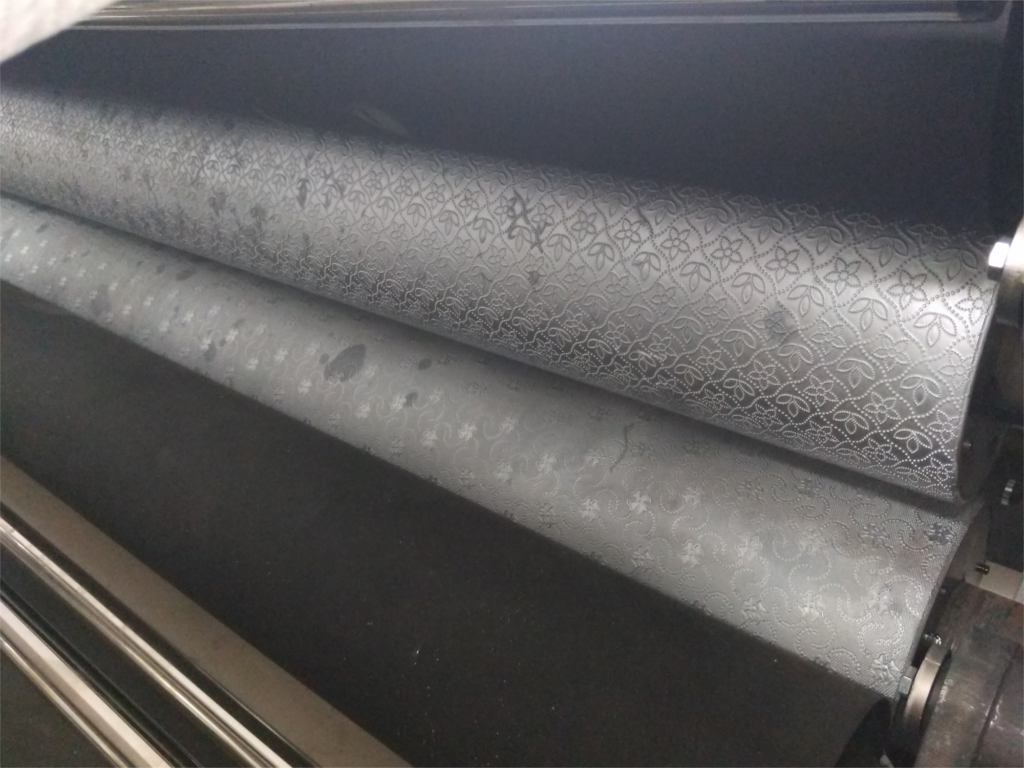

5. Embossing:

- Texture Creation:To further increase the paper towel’s absorbency and strength, the paper may undergo embossing, where patterns are pressed into the paper using rollers with raised designs. Embossing can also add decorative patterns, enhance the paper’s feel, and improve its ability to pick up and retain liquids.